Industrial floor scales

This solution in a nutshell:

- Large range of platform scales

- Maximum weighing capacity of 300 kg up to 40 ton

- Choice of material dependent on usage

More than 175 years of experience

- Robust for sustainable use in industry

- Custom-made flexibility

- Customization possible

Are you looking for an effective solution for weighing products in an industrial environment?

We offer a wide range of industrial platform scales that are engineered and produced in-house.

First, we check how your products are manipulated. In other words: the way you will exactly weigh them on the weighing plate:

- Manually by an operator: for instance, for weighing products that stand on carts or norm trolleys in a production environment

- Manual or electric pallet truck

- Electrical stacker

- Forklift truck

- …

A first possibility is a built-in weighing plate. In this option, a weighing plate is built in the floor. Hence, you can easily place your products on the weighing plate.

The main advantage is that you can’t overload the platform scale at the sides. Therefore, your platform scale gets a longer service life.

Moreover, the weighing plate can be executed with dimensioned load cells. This way, you can also load the built-in weighing plate by means of an electrical pallet truck or a forklift truck.

We also provide a pit frame to pour. For this, we make use of a detailed pit plan.

This way, we can ensure that the dimensions of the pit are appropriate and that the borders of the pit around the weighing plate are perfectly protected.

If you are working in an environment that is regularly cleaned, we can also offer you a built-in weighing plate with gas springs.

Therefore, one can tilt the platform scale open, without using any equipment. This way, the pit can easily be cleaned and one can weigh in a hygienic way.

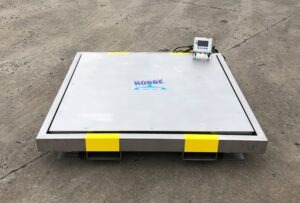

A second possibility is a build-up weighing plate or an above-ground weighing plate. In this option, the weighing plate is mounted in a fixed way on the floor.

If the above-ground weighing plate is loaded by means of a forklift truck, we can also provide a rubber bump to protect.

You can also choose a low-profile version, with which the slope of your loading ramp is rather limited. This way, one can load the weighing plate more easily by means of a manual or electrical pallet truck.

If the plate weigher is only loaded by means of a forklift truck or stacker, we have an industrial solution.

Our removable weighing plate with rubber bumps is protected against loading with a fork lift truck.

Thanks to the special construction of this industrial weighing plate, it is possible to provide a bumper profile around the weighing plate.

Therefore, there is no contact sideways with the weighing frame, when loading or unloading the products. Hence, a longer service life is ensured.

Moreover, we provide tubes at the bottom of the weighing plate in this version. This way, one can easily move the weighing plate, without any intervention of a Robbe technician.

Thanks to the flexible features of this weighing device, the weighing plate is an ideal solution when one has to weigh on different locations.

An additional advantage is that one can easily clean under and around the weighing plate.

The maximum weighing capacity is adapted to the loading of the products and goes from 300 kg up to 40 t.

Also, the size of this weighing plate is adapted to the load.

You can opt for standard dimensions (small up to big), but customization is also possible, as we design and produce our platform scales in-house.

The choice of material and follow-up is adapted to the environment and the usage.

Common materials are lacquered and galvanised steel, as well as RVS 304 or 316 with blasting afterwards.

Other treatments are possible too, if necessary.

Whenever the device is installed in an ATEX environment, we can also offer a weighing plate that meets the requirements of the specific ATEX zonation.

If the weighing is done with commercial purposes, we like to offer a calibrated platform scale with a certificate.

As a matter of fact, we have the necessary accreditation to execute this in-house.

Whenever the weighing is done in a production environment, we can also present an official inspection certificate, for the purpose of a quality audit or other norms.

All the platform scales are properly adjusted in our in-house workshops and are ready to use whenever they are delivered. If necessary, we can execute the adjustments on site.

Our own technicians take care of the delivery and installation of the platform scales. If necessary, they can take care of the initial operation too.

If required, a customization is possible too. For instance: a roller conveyor on the weighing plate, a seatback or raised feet.

Regarding the weight indicator (a display with an indication of the weight) we like to propose a solution according to the applications of the device that is protected against the usage in a specific environment.

If additional data have to be registered during the weighing, we are happy to offer you the necessary hardware and software for automation of weight registration and data processing.

For this, we prefer to offer the intelligence on PC and software level. Hence, we can guarantee a flexible, intuitive and up-to-date usage.

You will find more information by clicking on this link.

Can we help you?

Describe your project and needs by filling in the form below. We will answer you within two working days and explain how we can help you.

View more solutions

Industrial scales

Scales for industrial usage in production environment with possibility of customization.

Automation and software for industrial weighing devices

Solutions This solution in a nutshell: Large range of scales Maximum weighing capacity of 3 kg up to 150 kg Choice of material dependent on

Can we help you?

Describe your project and needs by filling in the form below. We will answer you within two working days and explain how we can help you.