Filling IBCs and barrels

This solution in a nutshell:

- Filling IBCs, drums, barrels and bidons

- Filling above and below level

- ATEX environment

- Hygienic design for food

- Stand-alone or in filling line

More than 175 years of experience

- Focus on ergonomics, efficiency and automation

- Custom-made flexibility

- Chemistry industry

- Food industry

- Experience in very diverse products (hydrocarbons, glues, silicones, oils, paint, …)

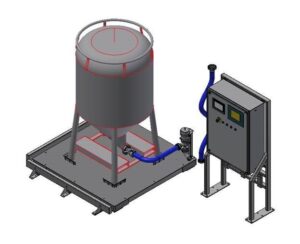

For the filling of liquid products in Intermediate Bulk Containers and barrels, we dispose of the appropriate filling machines.

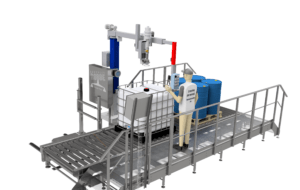

The Neptunus automatic filling system is the perfect filling machine for the filling of IBCs, drums, barrels andbidons. This machine is adjustable in height by means of the swivelling arm, the filling column can perfectly be placed above the filling hole.

The filling machine can also be combined with a scale. Therefore, the IBC or pallet with barrels is manually moved. Moreover, this machine can also be used in a filling line with conveyors and roller conveyors.

The filling can be done both above and below level.

In case of an above level filling, the filling column will always remain above the liquid level. Therefore, the filling column can remain in the filling hole or hang above it. In case of a below level filling, the filling column will remain in the product. In this option, the filling column will always remain at the same distance, under the liquid level. Moreover, the machine will guide the filling column upwards, with the same speed as when the liquid level rises.

We have already experience in filling very viscous liquids like silicones, glues, honey, … Even very liquid products like organic hydrocarbons, citric acids, … have no longer secrets for us. We are also familiar with paint and alkydresins.

We design specific machines for usage in an ATEX environment, in which an explosive atmosphere can occur during filling. Robbe Industries has many references in the chemistry industry regarding filling installations in an ATEX environment.

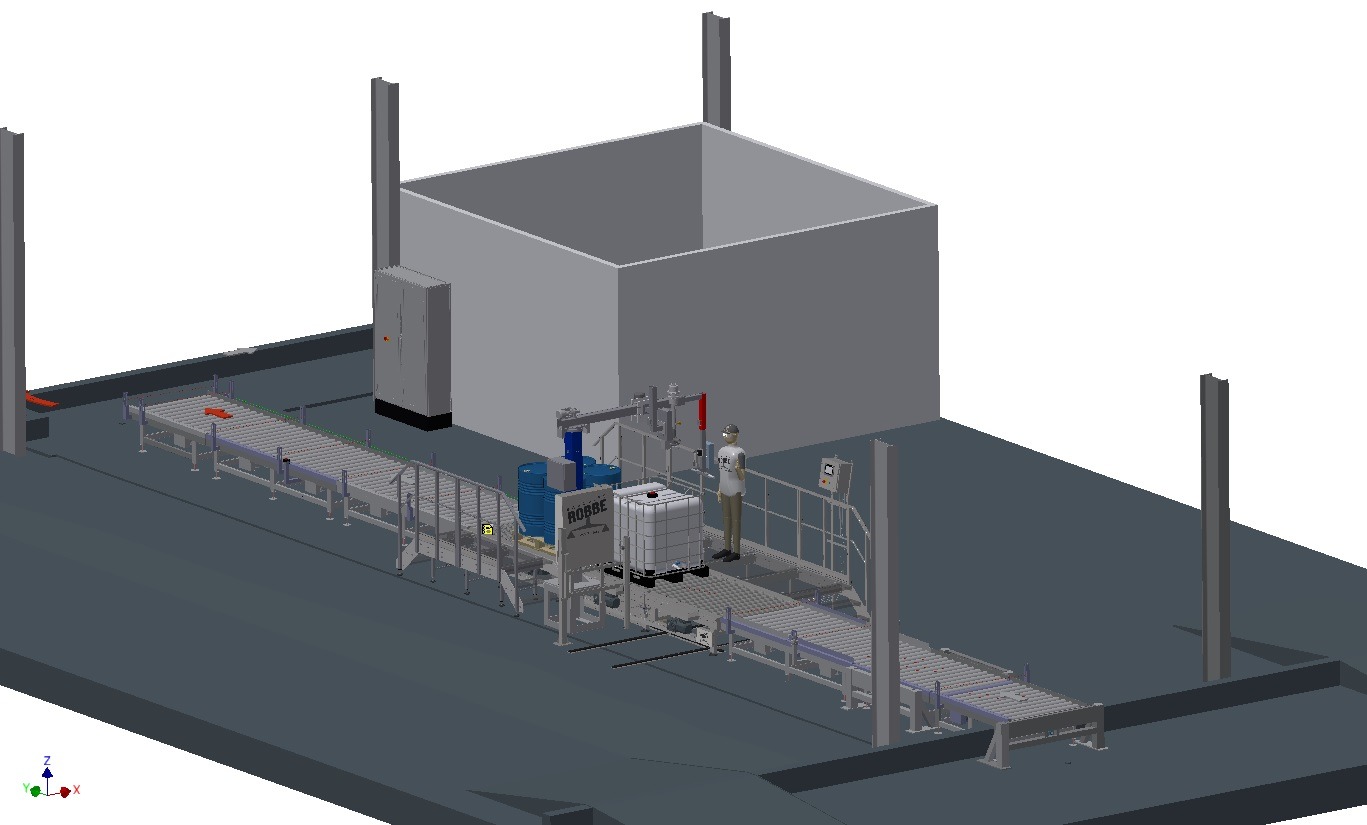

The filling machine can perform as a stand-alone application. Therefore, a separate scale or pallet weigher is used to weigh the IBC or pallet with barrels. After filling, this is removed by the operator. Multiple barrels on the same pallet can be filled too, for instance four barrels of 200 kg. However, the disadvantage of this set-up is that a lot of time is waste during removing and installing packages. This can only happen whenever the machine is not filling.

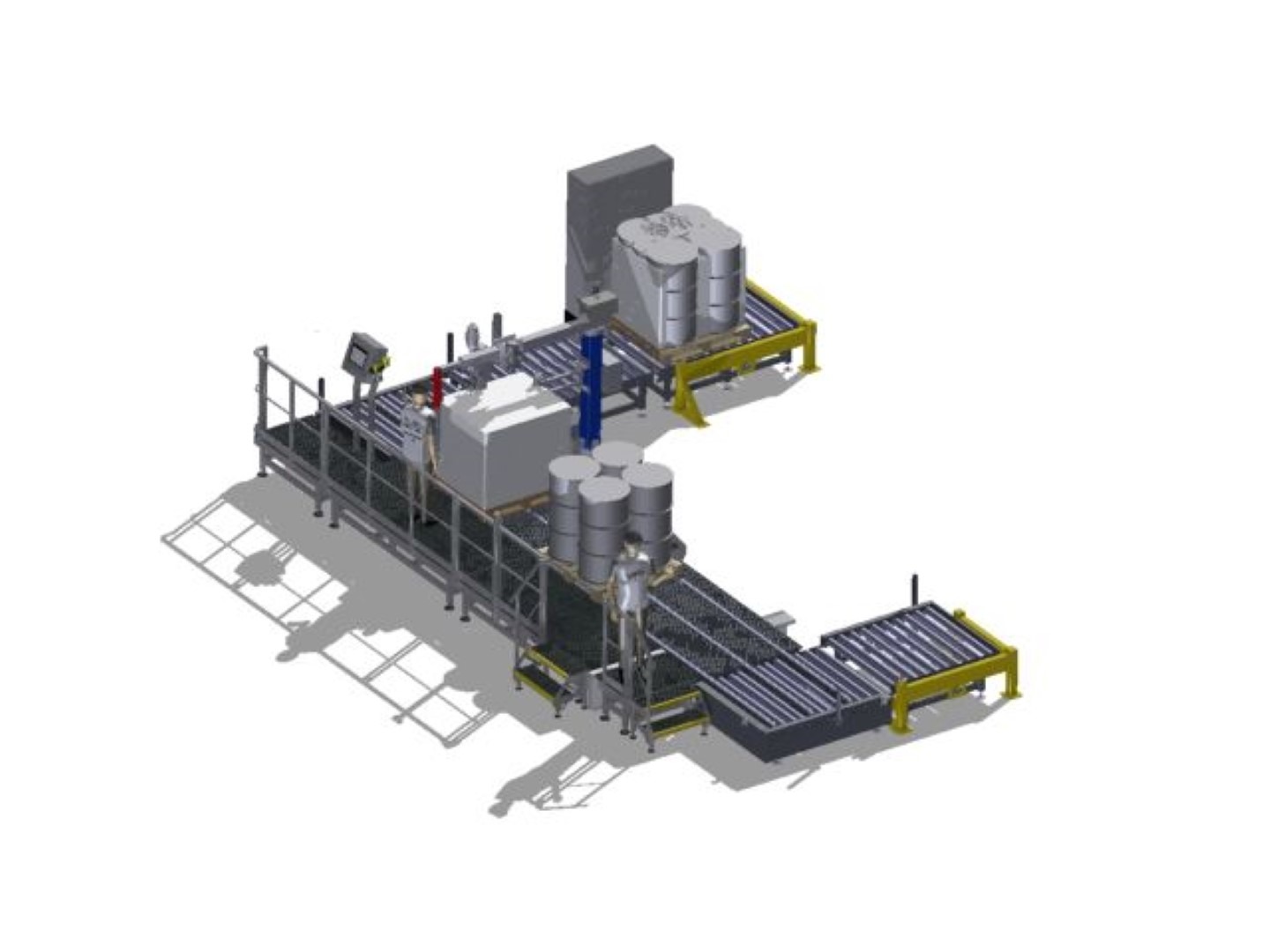

In case of a filling line, an input buffer and output buffer with roller conveyors is provided. These conveyors can be loaded independently. Therefore, this operation is very time saving. While the filling machine is operating, the operator can prepare a new range of empty IBCs or pallets with barrels or he can remove a filled range. It is also possible to integrate a lock, so the forklift cannot enter the filling room. This is very important in a food environment and in chemical installations. Via high-speed roll-up doors, the empty and filled IBCs or pallets with barrels can enter the clean room automatically.

We can customize these filling lines for our customers. Therefore, we take care of the programming too. This will be written in-house. In case of customization, we take all your requirements into account and work in a very flexibleway.

If you want to go the extra mile, our Lympha filling robot can detect the filling hole automatically. Via an integrated vision system, this machine can move to the filling hole automatically. In case multiple packages are stacked on a pallet, e.g. barrels or bidons, the machine can execute the fillings automatically in an autonomous way. Even further automation is possible. Hence, the lids can be removed automatically for the filling. After the filling, the lids can be replaced automatically too.

For the filling of smaller packages, like jerrycans, bidons and buckets by weight, we have the appropriate filling machines too. For these packages, the filling is executed according to the filling unit. They can be filled both above and below level. For small ranges, this machine can be operated by an operator or it can be automated via a robot or cobot. Of course, we can also provide a palletising robot to stack the filled packages.

Can we help you?

Describe your project and needs by filling in the form below. We will answer you within two working days and explain how we can help you.

View more solutions

Filling bidons and jerrycans automatically

Filling liquid products in bidons and jerrycans in ATEX environment.

Filling liquid products automatically in ATEX

Filling liquid products in IBC and barrels in ATEX environment.