Loss-in-weight

Specifications:

- Reliable Siemens components

- Incorporation in new or existing situation

- High flow rates

- High accuracy

- ATEX environment

- An efficient solution for all bulk material

More than 175 years of experience

- Our team is very flexible

- Custom-made

- Always in time

If you want to monitor or dose the supply of a certain product, we can support you with our wide range of weighfeeders and loss-in-weight modules.

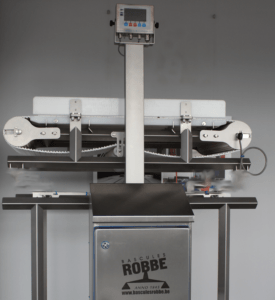

The complete installation existing of a hopper, screw or conveyor belt, is continuously weighed. Moreover, the differences in weight are registered per time unit. This way, the product flow can be calculated by the weight indicator.

Depending on the product, you can choose between a conveyor belt and a screw feeder.

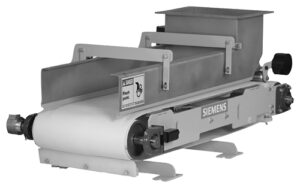

As a matter of fact, the Siemens weighfeeder is a compact solution. This device is ideal for the installation within existing buildings. This heavy-duty weighfeeder can be installed in different industries from agriculture to recycling, food and chemistry industry.

Weighing electronics

The WT241 is based on the Siemens WP241 PLC weighing module. This weighing module can be controlled in a very easy and intuitive way by means of the 4’’ colour touchscreen. With this screen, you can control your belt weigher and consult the weighing results in no time. The whole is built in a cabinet of stainless steel with an IP65 degree of protection. That’s why this weight indicator is used in numerous industries like food, pharma, chemistry, … but also heavy industries like mining, steel industry, recycling, cement, …

The weighing module WP241 can easily be integrated in a SIMATIC S7-1200 via the Siemens TIA Portal environment. At the same time, this module can operate as a stand-alone system, without SIMATIC CPU too. This module is designed for different applications in continuously weighing (belt weighers, weigh feeders, …).

This weighing module is provided with an on-board ethernet exit (RJ-45) and can be connected to an Ethernet/IP Modbus TCP/IP and Profinet devices. Moreover, there is a Modbus RTU (RS-485) exit. Results and data can easily be visualized via a HMI touchscreen panel.

Moreover, the module offers the possibility to simulate the flow rates and loadings. Hence, all alarms and functions in the connected systems can easily be tested during the implementation.

Installation

Our experienced technicians can execute the complete built-in weighfeeder. With the installation of weighfeeders with high precision, there is a lot involved. First, an employee of the study department will pay a visit on site. Then all necessary dimensions are taken into account. Subsequently, the necessary accessories for the installation are produced in our workshop. This way, the weighfeeder is correctly built and the installation will be ready for use in no time.

We have already built a lot of weighfeeders. You can count on us for the installation, adjustment and technical support. Moreover, Robbe Industries is an approved OEM partner of Siemens. This means we work closely together with the experts of Siemens Siwarex Weighing Technology. That’s why a lot of our employees have already got an education in Germany regarding this business.

In case you have any question regarding weighfeeders, please do not hesitate to contact us!

Can we help you?

Describe your project and needs by filling in the form below. We will answer you within two working days and explain how we can help you.

Can we help you?

Describe your project and needs by filling in the form below. We will answer you within two working days and explain how we can help you.