Weighfeeder Cortès

This solution in a nutshell:

- Weighfeeder for tobacco

- Light product

- Weighing accurately

- Integration with existing PLC

- Integration in current environment

- Siemens components, Robbe know-how!

Why the customer chose Robbe Industries …

- Automation

- Custom-made flexibility

- Very liquid products: grains, salts, premixes, …

Customer data

Company

Cortès, Handzame

Website

www.jcortes.com

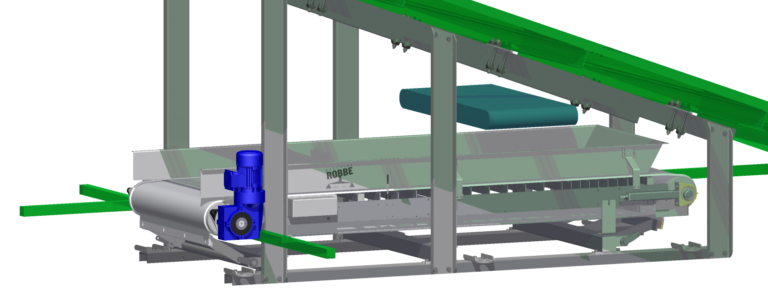

Integration of Siemens weighfeeder for adding flavours to tobacco

Required production process

In order to realize an optimal production, the tobacco is taken out of the box. Subsequently, it is weighed on a conveyor belt and by means of these flow rates, a certain quantity of flavour has to be atomised over the tobacco. All this is mixed in a mixing box and ready for further processing in the factory.

Problem

There was a need for a correct weighing system in order to add the right quantity of flavour to the tobacco that passes on the belt, by means of the flow rate. This is not only important to get the right flavour, but cannot exceed the legally determined limits.

Tobacco is a very light product, so there is only a light weight on the conveyor belt.

The belt weigher had to be built in an existing environment, between the current machines and on a ceiling.

Solution

In order to know how much tobacco, as a very light product, is actually passing on the conveyor belt, Robbe Industries – as an OEM partner of Siemens – checked the Sitrans WW200 weighfeeder. Despite the difficulty of the light product, we knew (because of our experience) that this wouldn’t cause any problem for this weighfeeder, as we can count on the very accurate reading of the Siemens Siwarex WP241 module.

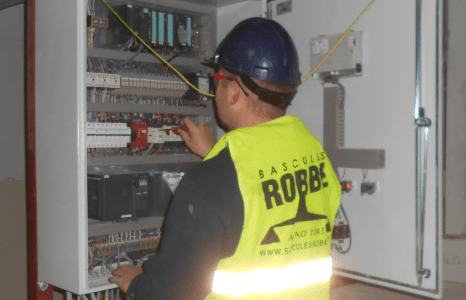

In this case, the weighing data were integrated by Robbe Industries, by means of the existing PLC, via an intermediate module. However, the Siwarex WP241 can work perfectly as stand-alone system as well.

Our employees measured the current ceiling structure and the draft was made up in 3D. Subsequently, the design for the hanging system was executed in the smallest details, so we wouldn’t be surprised when assembling the system. We transferred the necessary turning, milling and laser pieces digitally to our workshop, via specific CADCAM software. Hence, we could weld a solid construction in our proper welding department.

The installers of Robbe Industries managed to execute the whole rebuilding in half a day. Therefore, the downtime was minimized a lot.

In short, because we have everything in-house, Robbe Industries really makes a difference as a Siemens integrator.

We have the necessary knowledge and flexibility to offer such a project as a custom solution with high-quality products. Moreover, our customer gets a single point of contact during the entire project.

Quote of the customer

“This weighfeeder is in operation for almost a year now and we can only be satisfied” says Kris Versyck of Cortès.

Can we help you?

Describe your project and needs by filling in the form below. We will answer you within two working days and explain how we can help you.

View more realisations

Mobile discontinuous totalising hopper scale

Dust-free, mobile ship unloader with > 500 m3/h capacity.

Belt weighers in recycling industry

Follow-up of production flow in extreme environment.

Can we help you?

Describe your project and needs by filling in the form below. We will answer you within two working days and explain how we can help you.